HARD SPOT INSPECTION TROLLEY - English -

Page 68/84

Operating and Maintenance Instructions

adaptaed from: https://app.box.com/s/c6qfgtuhfg1yd2ottrfum98x8jmg7rn3

| Hard spot inspection trolley • PLAMAT-M •

18201 |

|

| Operating and

Maintenance Instructions • V2.0 |

Scanning procedure

|

6 SCANNING PROCEDURE

6.1 Overview

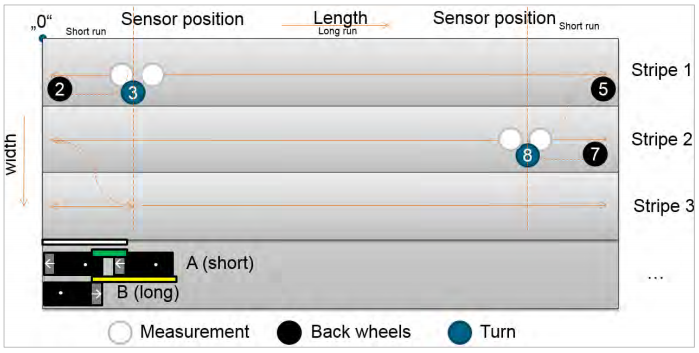

A complete plate is scanned in terms of stripes. Each stripe consists of a short and a long run.

In order to prepare the plate for testing, the usage of a shock cord

with chalk is recommended to indicate the stripes with a width of 240

mm on the plate.

Proceed according to the followings steps:

1. Perform the short run first (Figure 63, stripe 1, from right to left)

2. Ensure the tracked distance is larger than the length of the trolley.

> When reaching the plate edge, the software indicates to swap to the long run.

3. When changing from short to long run, turned around the trolley (#3).

> Then the long run is performed (in below figure from left to right) and stripe 1 has been completed successfully.

4. Move the trolley backwards over a short distance to start with the short run for stripe 2.

5. Repeat the steps 1 to 5, but on the other side of the plate.

After having completed above procedure for the entire plate, you can

decide whether the stripes are combined in meander-like or

parallel-like pattern.

Then, a complete 2D-Scan of the plate is provided.

Figure 63: Overview of inspection procedure

| ROSEN and IZfP Page 68 of

84 |

Confidential! |

|