HARD SPOT INSPECTION TROLLEY - English -

Page 56/84

Operating and Maintenance Instructions

adaptaed from: https://app.box.com/s/c6qfgtuhfg1yd2ottrfum98x8jmg7rn3

| Hard spot inspection trolley • PLAMAT-M •

18201 |

|

| Operating and

Maintenance Instructions • V2.0 |

Calibration procedure

|

5 CALIBRATION PROCEDURE

5.1 Introduction

In order to determine material properties like hardness quantitatively,

a calibration must first be performed. Depending on the chemical

composition of the steel and its production process, different

combinations of microstructures and other influencing quantities have

to be distinguished. Independent testing statistics are necessary to

separate microstructure and other influences by suitable conjunction of

these testing statistics.

Generally, the measurement may be affected by different, disturbing

influences such as scale, residual magnetization, residual stress and

other potential parameters. As a direct consequence, an individual

calibration would be required for each influence, steel grade and the

combination thereof. Different microstructures (ferrite, perlite,

bainite, ...), hardening depths and their combination with the

influencing parameter may imply a huge range of different reference

plates, which would have to be provided by the steel manufacturer.

As an alternative approach, a machine learning algorithm for supervised classification is used here.

5.2 Classification methodology

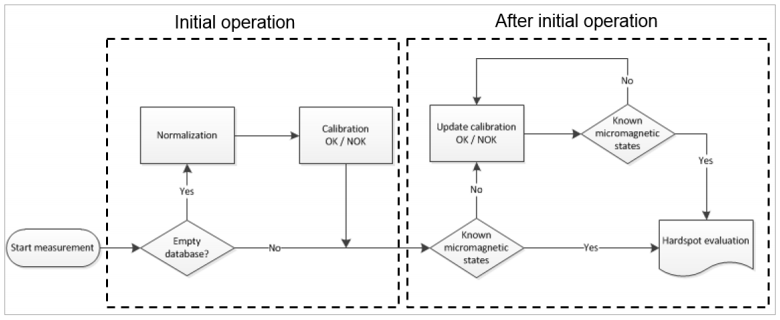

The calibration methodology used here is based on a machine learning

classification algorithm using the Euclidian distance between

nearest-neighbors in parameter space. The pattern of the magnetic

testing statistics of an unknown sample will be compared with all the

pattern of the data in the calibration data base and the nearest

neighbor in relevant parameter space will be investigated. The target

value of the found nearest neighbor will be the resulting target value

for the unknown sample.

The inspection trolley does not provide absolute hardness. Therefore,

the detection of unknown micro-magnetic states has to be confirmed via

mechanical evaluation with mobile hardness testing (Leeb, UCI) as

absolute reference. The calibration base is successively updated and

extended with new known micro-magnetic states after an initial

operation.

Figure 57: Overview of machine learning procedure

| ROSEN and IZfP Page 56 of

84 |

Confidential! |

|