HARD SPOT INSPECTION TROLLEY - English -

Page 25/84

Operating and Maintenance Instructions

adaptaed from: https://app.box.com/s/c6qfgtuhfg1yd2ottrfum98x8jmg7rn3

| Hard spot inspection trolley • PLAMAT-M •

18201 |

|

| Operating and

Maintenance Instructions • V2.0 |

Structure and handling of the trolley

|

3.2 Power supply modes

Two different power supply modes are available for running the detection system:

a) Operating via batteries/accumulators

b) Operating via mains

3.2.1 Operating via battery

For operating the trolley via battery/accumulator, a Lithium-ion based

accumulator with 24 V DC and a minimum capacity of 100 Ah is required

to operate the trolley for at least 6 hours.

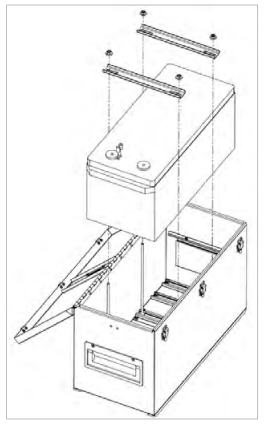

The accumulator is located in an aluminum housing. The lid of the

housing hosts an ODUMac connector which connects the battery with the

electronics.

Batteries have been chosen and are provided by the user which are

easily available on the local market. The trolley requires a supply

voltage of 24 V DC. The batteries used for this trolley are from the

company “energysource”. Two LEDs on top of the battery provide

information on the charging and capacity status. Using light guides and

a plastic interface for the LEDs on the battery, the corresponding

status is visible from the outside of the housing via battery level

indicator.

In case the battery has to be exchanged, three quick clamps can easily

be opened to get access to it. The battery is firmly fixed in the

housing by threaded bars and brackets. They can easily be opened.

Batteries with maximum dimensions of 250 x 225 x 500 mm (H x W x D)

are suitable for the housing.

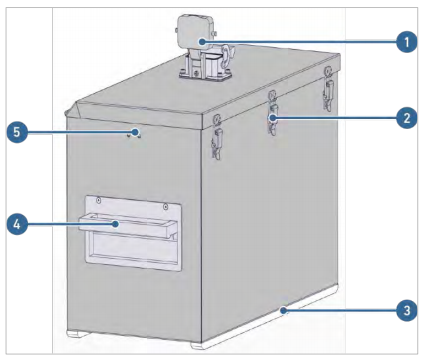

Figure 18: Battery housing

Table 4: Batteruy housing

Pos.

|

Description

|

| 1

|

Socket

|

| 2

|

Instep closure

|

| 3

|

Glide bar

|

| 4

|

Latch

|

| 5

|

Battery level indicatorr

|

The following illustrations show the wiring scheme of the battery housing and the ODU-Mac connector:

Figure 19: Wiring scheme battery housing

Figure 20: ODU-MAC connector pin assignment

| ROSEN and IZfP Page 25 of

84 |

Confidential! |

|