HARD SPOT INSPECTION TROLLEY - English -

Page 39/84

Operating and Maintenance Instructions

adaptaed from: https://app.box.com/s/c6qfgtuhfg1yd2ottrfum98x8jmg7rn3

| Hard spot inspection trolley • PLAMAT-M •

18201 |

|

| Operating and

Maintenance Instructions • V2.0 |

Software 3MA-X8 MMS

|

4.4 Tab: Inspection

The Inspection tab is the first panel shown per default after starting the MMS software and loading a module.

This view provides the inspection results.

4.4.1 Overview

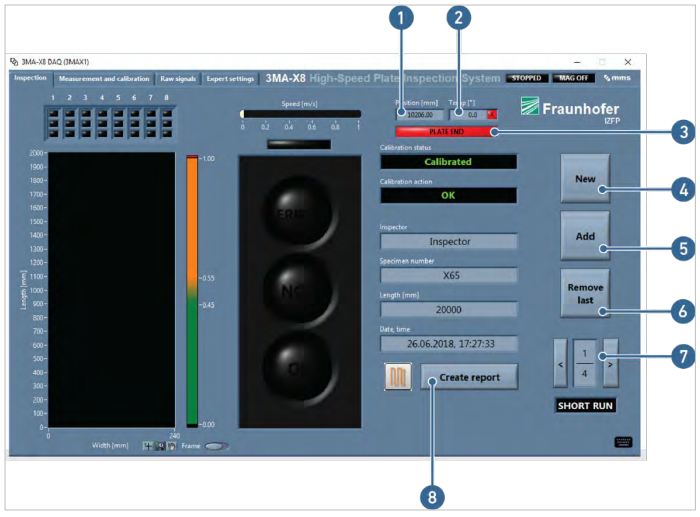

The following two illustrations describe the elements of the Inspection tab, here without any measurement results

Figure 38: Overview of Inspection tab (1)

Table 10: Elements on the Inspection tab (1)

Pos.

|

Description

|

| 1

|

Speed

|

| 2

|

Calibration status

|

3

|

Calibration action

|

4

|

User and measuremente information

|

5

|

Create report

|

6

|

Measurement display

|

7

|

Frame size full/moving

|

8

|

Mapped sensor signals

Green = Ok

Orange = NOK

Red = error

Black = not tested

|

9

|

Measure distance

|

10

|

Single probe head signals

|

The user information, i.e. name of Inspector, is retrieved from the windows login information.

The specimen number can be inserted manually or via bar code reader.

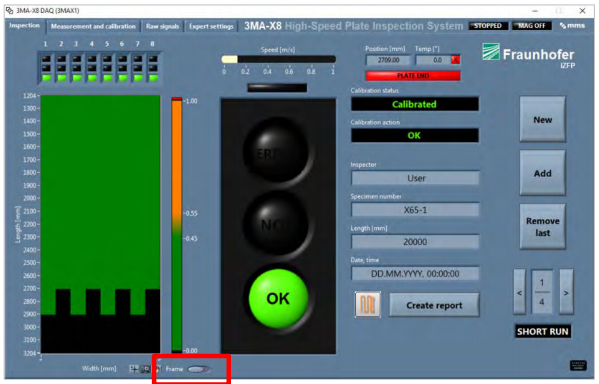

Figure 39: Overview of Inspection tab (2)

Figure 39: Overview of Inspection tab (2)

Table 11: Elements on the Inspection tab (2)

Pos.

|

Description

|

| 1

|

Actual position

|

| 2

|

Temperature

|

3

|

Plate end detection

|

4

|

New mapping trace

|

5

|

Add new mapping trace

|

6

|

Remove last mapping trace

|

7

|

Active mapping trace

|

8

|

Create report file

|

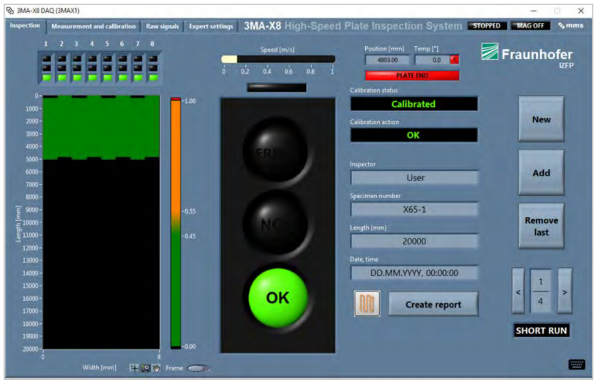

During a measurement, the Inspection tab shows a measurement carpet, where the view can be switched between static full size or moving size with the Frame button:

Figure 40: Influence of Frame button on measurement progress

Figure 40: Influence of Frame button on measurement progress

| ROSEN and IZfP Page 39 of

84 |

Confidential! |

|