HARD SPOT INSPECTION TROLLEY - English -

Page 16/84

Operating and Maintenance Instructions

adaptaed from: https://app.box.com/s/c6qfgtuhfg1yd2ottrfum98x8jmg7rn3

| Hard spot inspection trolley • PLAMAT-M •

18201 |

|

| Operating and

Maintenance Instructions • V2.0 |

Fundamental principles

|

2.3 Eddy current

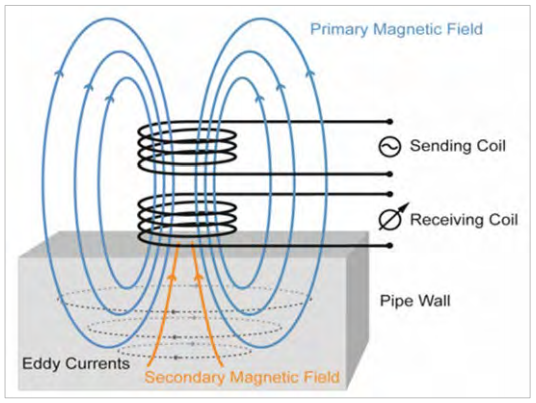

The EC testing method is based on the approach of generating electrical currents in

conductive materials, here the pipe wall. The figure below summarizes the principle. An

alternating electric current with defined amplitude and frequency is applied to a coil system.

The driving current generates an alternating primary magnetic field which causes eddy

currents to flow in the surface of the nearby pipe wall by mutual inductance. The currents in

the pipe wall produce a secondary magnetic field which is opposed to the primary field

inducing it. Defect damage such as corrosion leads to a change of the EC’s flow direction,

which influences the mutual inductance. This can be described by a variation in the electrical

impedance of the coil, i.e., its Ohmic resistance and inductive reactance.

The impedance is usually measured across a bridge circuit in which any imbalance can be

measured accurately. On the basis of this imbalance, material inhomogeneities can be

detected and their properties determined by the evaluation of the amplitude and the phase

shift between the input and output signals.

Figure 4: The EC principle

In

addition to material properties such as the electric conductivity and

magnetic permeability, the frequency of the input signal also

determines the so-called skin depth of eddy currents.

The skin depth is a measurement of the distance to which an alternating

current can effectively penetrate beneath the surface of a conductive

material, in this case the pipe wall.

For suitable frequencies and standard steel grades the skin depth for

carbon steel is well below 1 mm. Thus, the EC approach can be

considered to be a surface-sensitive method.

The magnetic permeability generally depends on the operating point of magnetization, which usually comprises:

- demagnetized operation point

- residual magnetized operating point

Figure 5: Magnetic hysteresis loop and operating points

Since the EC approach considered here is surface- bonded, surface

influences may have and disturbing character, e.g. tinder, roughness,

etc.

The following micro-magnetic parameters are considered for the EC analysis:

| Zmax [Ohm] |

maximum magnitude of the impedance |

| Zmin [Ohm] |

minimum magnitude of the impedance |

| Zmean [Ohm] |

averaged magnitude of the impedance |

| Phizmax [rad] |

maximum phase of the impedance |

| Phizmin [rad] |

minimum phase of the impedance |

| Phizmean [rad] |

averaged phase of the impedance |

| W3Z [Ohm] |

3 % widening of the eddy current loop |

| W10Z [Ohm] |

10 % widening of the eddy current loop |

Figure 6: EC impedance plane

| ROSEN and IZfP Page 16 of

84 |

Confidential! |

|