HARD SPOT INSPECTION TROLLEY - English -

Page 14/84

Operating and Maintenance Instructions

adaptaed from: https://app.box.com/s/c6qfgtuhfg1yd2ottrfum98x8jmg7rn3

| Hard spot inspection trolley • PLAMAT-M •

18201 |

|

| Operating and

Maintenance Instructions • V2.0 |

Fundamental principles

|

2 FUNDAMENTAL PRINCIPLES

2.1 Introduction

Steel manufacturing and steel

processing industries require nondestructive testing methods for

quality control. For this purpose hardness, case depth, strength and

residual stresses are major quality features in demand. Ferromagnetic

steels and cast iron show a distinct correlation between magnetic

behavior und mechanic technological materials characteristics.

Hard-magnetic materials, i.e., materials that are difficult to

magnetize or to degauss, mostly show mechanical hard and brittle

characteristics, while soft magnetic materials like pure iron use to be

mechanical ductile. Equally, residual and load stresses exert a

comparable influence on magnetic processes. Hence, in many cases these

nondestructively gauge-able magnetic properties can be used to analyze

mechanical material behavior and stress states.

The solution to address aforementioned

requirements is 3MA-X8. It is an acronym for “Micromagnetic

Multiparameter, Microstructure and stress Analysis“. Within fractions

of a second, the inspection system measure how hard- or soft-magnetic a

material is. Moreover, a multitude of different magnetic parameters are

determined which are correlated to different material properties or

residual and load stresses. By a pre-defined set of calibration samples

the 3MA method identifies the correlation between magnetically measured

parameters and the target values as required by the customer. This is

realized by mathematical statistical tools like pattern recognition and

regression analysis.

2.2 Measurement approach

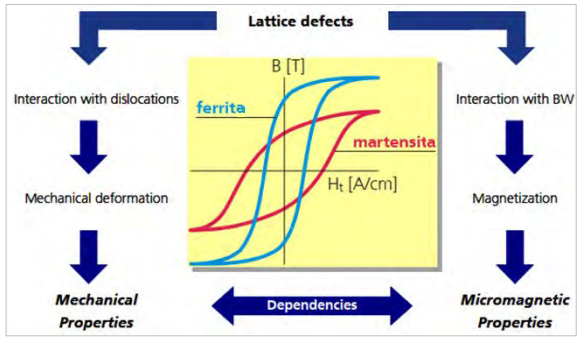

3MA is a nondestructive electromagnetic

testing method, whereby testing statics were derived during magnetic

hysteresis cycles. 3MA evaluates electrical and magnetic parameters

which are influenced for example by the microstructure, hardness,

hardness depth, yield strength and residual stress states. Figure 1 is

pointing up the correlation between mechanical and magnetic material

properties. The mechanical properties of a material is resulting from

its microstructure, dislocations in the lattice and the mechanical

deformations by the production procedure. The micro magnetic properties

of a material are characterized by the dynamic magnetic behavior, which

is influenced by the interaction of Bloch walls (BW) with dislocations

or lattice defects.

Figure 1: Correlation between mechanical and magnetic material properties

| ROSEN and IZfP Page 14 of

84 |

Confidential! |

|