No. |

Questões | [Ref] |

| 1 |

Qual dos seguintes itens não faz parte do escopo do ASME BPVC Seção V Artigo 8 2013 Non Mandatory Appendix II

Qual dos seguintes itens não faz parte do escopo do ASME BPVC Seção V Artigo 8 2013 Non Mandatory Appendix II

|

[01] |

| a) surface probes | ||

| b) multiparameter | ||

| c) multifrequency | ||

| d) heat exchanger tubes | ||

| 2 |

Quanto ao item II-820 GENERAL do ASME BPVC Section V Article 8 Non Mandatory Appendix II: "This Appendix also provides the methodology for

examining nonferromagnetic, heat exchanger tubing using the eddy current method and bobbin coil technique. By scanning the tubing from the OD side,

information will be obtained from which the condition of the tubing will be determined. Scanning is generally performed with a bobbin coil attached to a

flexible shaft pulled through tubing manually or by a motorized device. Results are obtained by evaluating data acquired and recorded during scanning."

Quanto ao item II-820 GENERAL do ASME BPVC Section V Article 8 Non Mandatory Appendix II: "This Appendix also provides the methodology for

examining nonferromagnetic, heat exchanger tubing using the eddy current method and bobbin coil technique. By scanning the tubing from the OD side,

information will be obtained from which the condition of the tubing will be determined. Scanning is generally performed with a bobbin coil attached to a

flexible shaft pulled through tubing manually or by a motorized device. Results are obtained by evaluating data acquired and recorded during scanning."

|

[02] |

| a) verdadeiro | ||

| b) falso | ||

| c) verdadeiro ou falso | ||

| d) verdadeiro e falso | ||

| 3 |

Qual item é essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

Qual item é essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

|

[03] |

| a) Personnel requirements | ||

| b) Data recording equipment manufacturer and model | ||

| c) Tube material | ||

| d) Tube numbering | ||

| 4 |

Qual item é não essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

Qual item é não essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

|

[04] |

| a) Tube examination surface preparation | ||

| b) Probe type and size | ||

| c) Mode of inspection - differetial or absolute | ||

| d) Examination frequencies, drive voltage, and gain settings | ||

| 5 |

Qual item é essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

Qual item é essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

|

[05] |

| a) Data recording equipment manufacturer and model | ||

| b) Scanning speed during insertion or retraction, no data recording | ||

| c) Maximum scanning speed during data recording | ||

| d) Data analysis parameters | ||

| 6 |

Qual item é não essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

Qual item é não essencial no MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING do ASME BPVC Section V Article, tabela II-821?

|

[06]

|

| a) Minimum digitalization rate | ||

| b) Identity of calibration reference standard(s) | ||

| c) Fixture location verification | ||

| d) Side of application - inlet or outlet | ||

| 7 |

A afirmação: "a change of a requirement in Table II-821 identified as an essential variable shall require requalification of the written procedure by demonstration." do item II-821.2 Procedure Qualification do ASME BPVC V Art 8

Mandatory Appendix II é?

A afirmação: "a change of a requirement in Table II-821 identified as an essential variable shall require requalification of the written procedure by demonstration." do item II-821.2 Procedure Qualification do ASME BPVC V Art 8

Mandatory Appendix II é?

|

[07] |

| a) verdadeira | ||

| b) falsa | ||

| c) verdadeira ou falsa | ||

| d) verdadeira e falsa | ||

| 8 |

A afirmação: "A change of a requirement identified as a nonessential variable requires requalification of the written procedure." do item II-821.2 Procedure Qualification do ASME BPVC V Art 8 Mandatory Appendix II é?

A afirmação: "A change of a requirement identified as a nonessential variable requires requalification of the written procedure." do item II-821.2 Procedure Qualification do ASME BPVC V Art 8 Mandatory Appendix II é?

|

[08] |

| a) verdadeira | ||

| b) falsa | ||

| c) verdadeira ou falsa | ||

| d) verdadeira e falsa | ||

| 9 |

No item II-822 PERSONNEL REQUIREMENTS do ASME BPVC V Art 8 Mandatory Appendix II é exigido o emprego de inspetores certificados para realização do ensaio de correntes parasitas:

No item II-822 PERSONNEL REQUIREMENTS do ASME BPVC V Art 8 Mandatory Appendix II é exigido o emprego de inspetores certificados para realização do ensaio de correntes parasitas:

|

[10] |

| a) verdadeiro | ||

| b) falso | ||

|

c) verdadeiro ou falso

|

||

| d) verdadeiro e falso | ||

| 10 |

ASME V Artigo 8 - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-830 EQUIPMENT

II-830.4 Bobbin Coils.

II-830.4.1 General Requirements.

ASME V Artigo 8 - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-830 EQUIPMENT

II-830.4 Bobbin Coils.

II-830.4.1 General Requirements.

|

[10] |

| a) Bobbin coils shall be able to detect artificial discontinuities in the calibration reference standard. | ||

| b) Bobbin coils shall have sufficient bandwidth for operating frequencies selected for flaw detection and sizing. | ||

|

c) Respostas a) e b).

|

||

| d) nenhuma das opções pertence ao item citado do código. | ||

| 11 |

Quanto ao item do ASME V Artigo 8: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-830 EQUIPMENT

II-830.5 Data Analysis System.

II-830.5.1 Basic System Requirements.

Está errado apenas o sub-item?

Quanto ao item do ASME V Artigo 8: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-830 EQUIPMENT

II-830.5 Data Analysis System.

II-830.5.1 Basic System Requirements.

Está errado apenas o sub-item?

|

[11] |

| a) The data analysis system shal be capable of displying eddy current signal data from all test frequecies. | ||

| b) The system could have multiparameter mixing capability. | ||

| c) The system shall be capable of maintaining the identification of each tube recorded. | ||

| d) The system shall be capable of measuring phase angles in increments of one degree or less. | ||

| e) The system shall be capable of measuring amplitudes to the nearest 0.1 volt. | ||

| 12 |

ASME V Article 8: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-830 EQUIPMENT

II-830.7 Digital Data Analysis System.

II-830.7.1 Display.

(d) The strip chart display shall be selectable so either the X or Y component of some examination frequency or mixed frequencies can be displayed.

ASME V Article 8: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-830 EQUIPMENT

II-830.7 Digital Data Analysis System.

II-830.7.1 Display.

(d) The strip chart display shall be selectable so either the X or Y component of some examination frequency or mixed frequencies can be displayed.

|

[12] |

| a) verdadeiro | ||

| b) falso | ||

| c) verdadeiro ou falso | ||

| d) verdadeiro e falso | ||

| e) Os aparelhos de correntes parasitas devem ser capazes de detectar e gravar sinais oriundos de alterações dimensionais, alterações metalúrgicas e depósitos de materiais, como produtos de corrosão, e por descontinuidades existentes na superfície interna, externa ou ambas dos tubos. | ||

| 13 |

ASME BPVC Sec V Art 8 2013 MAppd II: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-840 REQUIREMENTS

II-840.1 Recording and Sensitivity Level.

(b) The sensitivity for the differential bobbin coil technique shall be sufficient to produce a response from the through-wall hole(s) with a minimum vertical amplitude of 50% of the full Lissajous display height.

ASME BPVC Sec V Art 8 2013 MAppd II: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-840 REQUIREMENTS

II-840.1 Recording and Sensitivity Level.

(b) The sensitivity for the differential bobbin coil technique shall be sufficient to produce a response from the through-wall hole(s) with a minimum vertical amplitude of 50% of the full Lissajous display height.

|

[13] |

| a) verdadeiro | ||

| b) falso | ||

| c) verdadeiro ou falso | ||

| d) verdadeiro e falso | ||

| 14 |

Segundo o item:

ASME BPVC Sec V Art 8 2013 MAppd II: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.1 Equipment Calibration.

II-860.1.1 Analog Equipment. The following shall be verified by ____________ calibration:

Segundo o item:

ASME BPVC Sec V Art 8 2013 MAppd II: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.1 Equipment Calibration.

II-860.1.1 Analog Equipment. The following shall be verified by ____________ calibration:

|

[14] |

| a) monthly | ||

| b) weekly | ||

| c) annually | ||

| d) century | ||

| 15 |

Segundo o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.1 Equipment Calibration.

II-860.1.2 Digital Equipment. Analog elements of digital equipment shall be calibrated in accordance with II-860.1.1. Digital elements need not be calibrated.

Segundo o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.1 Equipment Calibration.

II-860.1.2 Digital Equipment. Analog elements of digital equipment shall be calibrated in accordance with II-860.1.1. Digital elements need not be calibrated.

|

[15] |

| a) verdadeiro | ||

| b) falso | ||

| c) verdadeiro ou falso | ||

| d) verdadeiro e falso | ||

| 16 |

Segundo o item:

ASME BPVC Sec V Art 8 2013 MAppd II: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.2 Calibration Reference Standards.

Não é verdadeiro o subitem:

Segundo o item:

ASME BPVC Sec V Art 8 2013 MAppd II: MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.2 Calibration Reference Standards.

Não é verdadeiro o subitem:

|

[16] |

| a) Calibration reference standards shall be manufactured from tube(s) of different material specification and nominal size as that to be examined in the vessel. | ||

| b) Tubing calibration reference standard materials heat treated differently from the tubing to be examined may be used when signal responses from the discontinuities described in II-860.2.2 are demonstrated to the Inspector to be equivalent in both the calibration reference standard and tubing of the same heat treatment as the tubing to be examined. | ||

| c) …. The as-built dimensions of the discontinuities and the applicable eddy current equipment response shall become part of the permanent record of the calibration reference standard. | ||

| d) Each calibration reference standard shall be permanently identified with a serial number. | ||

| 17 |

21. Segundo o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.2 Calibration Reference Standards.

II-860.2.2 Calibration Reference Standards for Differential and Absolute Bobbin Coils.

(a) Calibration reference standards shall contain the following artificial discontinuities:

Só não é verdadeiro o item:

21. Segundo o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.2 Calibration Reference Standards.

II-860.2.2 Calibration Reference Standards for Differential and Absolute Bobbin Coils.

(a) Calibration reference standards shall contain the following artificial discontinuities:

Só não é verdadeiro o item:

|

[17] |

| a) (1) One or four through-wall holes as follows: (-a) A 0.052 in. (1.3 mm) diameter hole for tubing with diameters of 0.750 in. (19 mm) and less, or a 0.067 in. (1.70 mm) hole for tubing with diameters greater than 0.750 in. (19 mm). (-b) Four holes spaced 90 deg apart in a single plane around the tube circumference, 0.026 in. (0.65 mm) diameter for tubing with diameters of 0.750 in. (19 mm) and less and 0.033 in. (0.83 mm) diameter for tubing with diameters greater than 0.750 in. (19 mm). | ||

| b) (2) A flat-bottom hole 0.109 in. (2.7 mm) diameter, 60% through the tube wall from the outer surface. | ||

| c) (3) Four flat-bottom holes 0.187 in. (5 mm) diameter, spaced 90 deg apart in a single plane around the tube circumference, 20% through the tube wall from the outer surface. | ||

| d) (4) One 1/16 in. (1.6 mm) wide, 360 deg circunferential groove 10% through from the tube outer surface. | ||

| 18 |

Segundo o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.3 Analog System Set-up and Adjustment.

II-860.3.1 Differential Bobbin Coil Technique.

(a) The sensitivity shall be adjusted to produce a minimum peak-to-peak signal of 1

V from the four 20% flat bottom holes or 2 V from the four through-wall drilled holes.

A afirmação do subitem é?

Segundo o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.3 Analog System Set-up and Adjustment.

II-860.3.1 Differential Bobbin Coil Technique.

(a) The sensitivity shall be adjusted to produce a minimum peak-to-peak signal of 1

V from the four 20% flat bottom holes or 2 V from the four through-wall drilled holes.

A afirmação do subitem é?

|

[18] |

| a) verdadeiro | ||

| b) falso | ||

| c) verdadeiro ou falso | ||

| d) verdadeiro e falso | ||

| 19 |

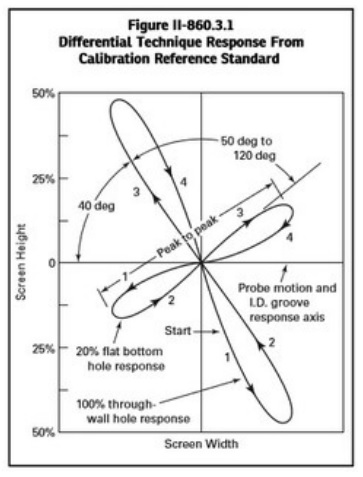

A figura pertence a qual sub item do ASME BPVC Section V Article 8 Mandatory Appendix II?

A figura pertence a qual sub item do ASME BPVC Section V Article 8 Mandatory Appendix II?

|

[19] |

| a) II-860.3.3 Hybrid Bobbin Coil Technique. | ||

| b) II-860.3.2 Absolute Bobbin Coil Technique. | ||

| c) II-860.3.1 Differential Bobbin Coil Technique. | ||

| d) Nenhuma das demais opções. | ||

| 20 |

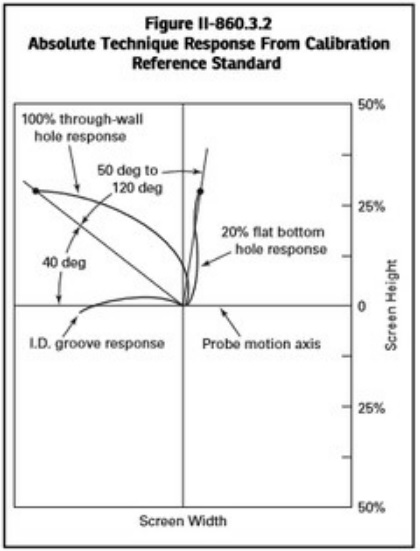

A figura pertence a qual sub item do ASME BPVC Section V Article 8 Mandatory Appendix II?

A figura pertence a qual sub item do ASME BPVC Section V Article 8 Mandatory Appendix II?

|

[20] |

| a) II-860.3.3 Hybrid Bobbin Coil Technique. | ||

| b) II-860.3.2 Absolute Bobbin Coil Technique. | ||

| c) II-860.3.1 Differential Bobbin Coil Technique. | ||

| d) Nenhuma das demais opções. | ||

| 21 |

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.3 Analog System Set-up and Adjustment.

II-860.3.2 Absolute Bobbin Coil Technique.

(a) The sensitivity shall be adjusted to produce a minimum origin-to-peak signal of 2 V from the four 20% flatbottom holes or 3 V from the four through-wall drilled holes.

Ele é verdadeiro (True) ou falso (False)

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-860 CALIBRATIONS

II-860.3 Analog System Set-up and Adjustment.

II-860.3.2 Absolute Bobbin Coil Technique.

(a) The sensitivity shall be adjusted to produce a minimum origin-to-peak signal of 2 V from the four 20% flatbottom holes or 3 V from the four through-wall drilled holes.

Ele é verdadeiro (True) ou falso (False)

|

[21] |

| a) Verdadeiro | ||

| b) Falso | ||

| c) Verdadeiro ou Falso | ||

| d) Verdadeiro e Falso | ||

| 22 |

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-870 EXAMINATION

Data shall be recorded as the probe transverses the tube in the extraction direction.

Ele é verdadeiro (True) ou falso (False)?

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-870 EXAMINATION

Data shall be recorded as the probe transverses the tube in the extraction direction.

Ele é verdadeiro (True) ou falso (False)?

|

[22] |

| a) Verdadeiro | ||

| b) Falso | ||

| c) Verdadeiro ou falso | ||

| d) Verdadeiro e Falso | ||

| 23 |

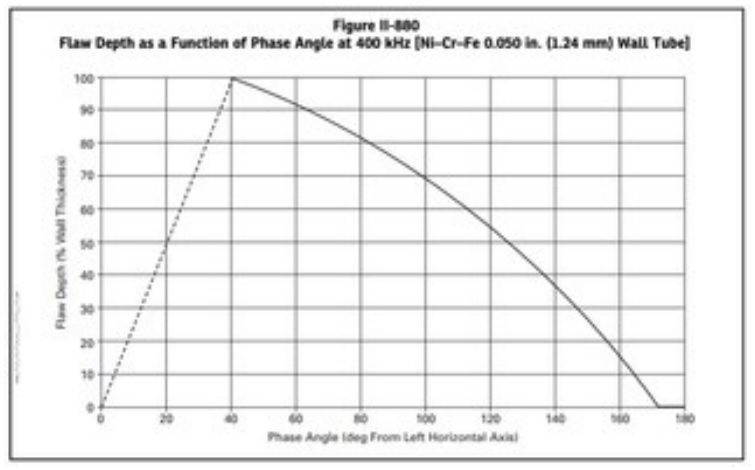

Considerando a figura, podemos afirmar que ela é relativa ao item:

ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-880 EVALUATION

Considerando a figura, podemos afirmar que ela é relativa ao item:

ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC HEAT EXCHANGER TUBING

II-880 EVALUATION

|

[22] |

| a) II-820.1 | ||

| b) II-820.2 | ||

| c) II-820.3 | ||

| d) II-820.4 | ||

| 24 |

Quais os sub itens do item: ASME BPVC Sec V Art 8 2013 MAppd II -

MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.1.1 Criteria. Indications reported in accordance with the requirements of this

Appendix shall be described in terms of the following information, as a minimun:

Quais os sub itens do item: ASME BPVC Sec V Art 8 2013 MAppd II -

MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.1.1 Criteria. Indications reported in accordance with the requirements of this

Appendix shall be described in terms of the following information, as a minimun:

|

[22] |

| a) location along the length of the tube and with respect to the support members | ||

| b) depth of the indication through the tube wall, when required by this Appendix [profundidade na espessura do tubo da indicação, quando requerida por esse apêndice] | ||

| c) signal amplitude [amplitude do sinal] | ||

| d) frequency or frequency mix from which the indication was evaluated [frequência ou frequência mixada na qual a indicação é avaliada] | ||

| e) all the others [todas as demais opções] | ||

| 25 |

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II -MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II-890.1.2 Depth. The maximum evaluated depth of flaws shall be reported in terms

of percentage of tube wall loss. When loss of tube wall is detemined by the analyst

to be less than 20%, the exact percentage of tube wall loss need not be recorded,

i.e., the indication may be reported as being less than 20%.

Ele é?

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II -MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II-890.1.2 Depth. The maximum evaluated depth of flaws shall be reported in terms

of percentage of tube wall loss. When loss of tube wall is detemined by the analyst

to be less than 20%, the exact percentage of tube wall loss need not be recorded,

i.e., the indication may be reported as being less than 20%.

Ele é?

|

[22] |

| a) Verdadeiro | ||

| b) Falso | ||

| c) Verdadeiro ou falso | ||

| d) Verdadeiro e Falso | ||

| 26 |

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.2 Records.

II-890.2.1 Records Identification. The recording media shall contain the following

information within each unit of data storage:

Qual dos sub itens a seguir não é verdadeiro:

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.2 Records.

II-890.2.1 Records Identification. The recording media shall contain the following

information within each unit of data storage:

Qual dos sub itens a seguir não é verdadeiro:

|

[22] |

| a) owner [proprietário] | ||

| b) plant site and unit [local da planta e unidade] | ||

| c) heat exchanger identification [identificação do trocador de calor] | ||

| d) data storage unit number [unidade de armazenamento de dados] | ||

| e) date of the requirement of the inspection [data da solicitação da inspeção] | ||

| f) serial number of the calibration standard [número de série do padrão de calibração] | ||

| 27 |

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.2 Records.

II-890.2.1 Records Identification. The recording media shall contain the following

information within each unit of data storage:

Qual dos sub itens a seguir não é verdadeiro:

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.2 Records.

II-890.2.1 Records Identification. The recording media shall contain the following

information within each unit of data storage:

Qual dos sub itens a seguir não é verdadeiro:

|

[22] |

| a) operator’s identification and certification level [identificação do inspetor e nível de certificação] | ||

| b) just one examination frequency [apenas uma frequência de ensaio] | ||

| c) mode of operation including instrument sample rate, drive voltage, and gain settings [modo de operação incluindo taxa de amostragem dos sinais, e ajustes de ganho] | ||

| d) lengths of probe and probe extension cables [comprimento da sonda e do cabo de extensão] | ||

| e) size and type of probes [dimensão e tipo das sondas] | ||

| 28 |

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.2 Records.

II-890.2.1 Records Identification. The recording media shall contain the following

information within each unit of data storage:

Qual dos sub itens a seguir não é verdadeiro:

Considerando o item: ASME BPVC Sec V Art 8 2013 MAppd II - MANDATORY APPENDIX II - EDDY CURRENT EXAMINATION OF NONFERROMAGNETIC

HEAT EXCHANGER TUBING

II-890 DOCUMENTATION

II.890.2 Records.

II-890.2.1 Records Identification. The recording media shall contain the following

information within each unit of data storage:

Qual dos sub itens a seguir não é verdadeiro:

|

[22] |

| a) probe manufacturer’s name and manufacturer’s part number or probe description and serial number [nome do fabricante da sonda e número de identificação da sonda ou descrição da sonda e número de série] | ||

| b) eddy current instrument serial number [número de série do instrumento de correntes parasitas] | ||

| c) probe scan direction during data extraction [direção de escaneamento durante a obtenção dos dados de inspeção] | ||

| d) application side — inlet or outlet [lado da inspeção - entrada ou saída de produto] | ||

| e) procedure identification and revision [identificação e revisão do procedimento] | ||